Hi, I got new account, Since the old account was not active...

Thanks for welcoming me again, This is my first topic.

I decided to build a 16610.

I bought JF No-Rehaut to the base case, Then I decomposed it apart and measured the size of each part.

First, In my opinion the tube should not be changed...lol

However in my case, the tube that was sturdy with instantaneous adhesive could not be removed easily,

so it was the most injured hindrance.

I'm very lucky to have few GEN tubes in my stock. I had rework to replace to JF case.

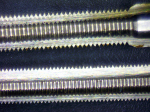

Some guys says GEN tube has M3-0.35 thread cutting. But it is a mistaken recognition.

Real GEN tube has M3-0.25 thread... I decided to process GEN tube side with mini lathe.

LEFT: JF defected / RIGHT: GEN used

REP tube's bottom shape is deferent from GEN.

GEN has a step to fall into the case, I think experienced guys well knew, ST case has step but is protruding.

And the part to become the ground contact surface of the case is thick.

1, Scrape down the step.

2, Make M3-0.35 thread to fit JF case. *JF has 0.35 thread.

LEFT: GEN without processing / RIGHT: GEN processed lathe and thread cutting.

I noticed where I replaced, but the position of the crown is high at JF case. Maybe it is about 0.3mm.

LEFT: early 16610 / RIGHT: JF

I should add a processing for the case side.

My next issue...

Thanks for welcoming me again, This is my first topic.

I decided to build a 16610.

I bought JF No-Rehaut to the base case, Then I decomposed it apart and measured the size of each part.

First, In my opinion the tube should not be changed...lol

However in my case, the tube that was sturdy with instantaneous adhesive could not be removed easily,

so it was the most injured hindrance.

I'm very lucky to have few GEN tubes in my stock. I had rework to replace to JF case.

Some guys says GEN tube has M3-0.35 thread cutting. But it is a mistaken recognition.

Real GEN tube has M3-0.25 thread... I decided to process GEN tube side with mini lathe.

LEFT: JF defected / RIGHT: GEN used

REP tube's bottom shape is deferent from GEN.

GEN has a step to fall into the case, I think experienced guys well knew, ST case has step but is protruding.

And the part to become the ground contact surface of the case is thick.

1, Scrape down the step.

2, Make M3-0.35 thread to fit JF case. *JF has 0.35 thread.

LEFT: GEN without processing / RIGHT: GEN processed lathe and thread cutting.

I noticed where I replaced, but the position of the crown is high at JF case. Maybe it is about 0.3mm.

LEFT: early 16610 / RIGHT: JF

I should add a processing for the case side.

My next issue...

Last edited: